What are the reasons that cause the rubber cylinder not to b

作者:點膠機廠家 日期:2019-03-13 11:43 瀏覽:

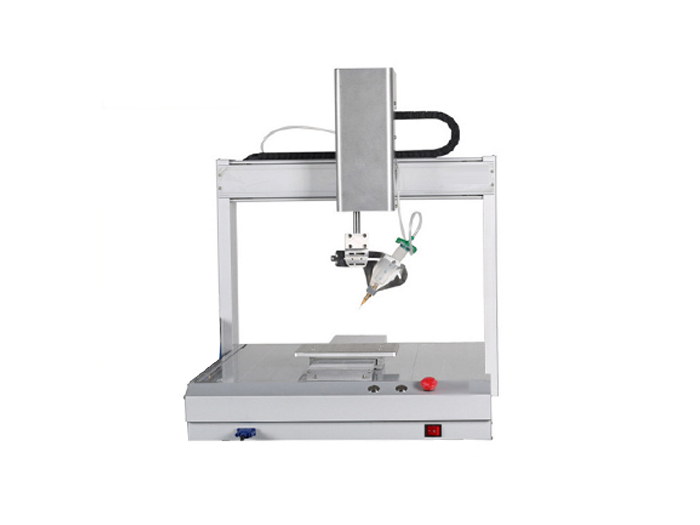

There are many kinds of reasons that affect the dispensing of semi-finished products. There are many feedback about the problem that the rubber valve does not glue or the rubber cylinder does not glue. The reason why the rubber cylinder does not glue is related to improper use and poor sealing, which is not conducive to the dispensing links of electronic products such as motherboard dispensing with high precision. The medium-sized dispensing machine has a certain popularity in Shenzhen dispensing machine industry and can be briefly introduced. Share the user's knowledge about the reason why the rubber cylinder does not glue.

Problem manifestation of poor sealing

Causes the rubber cylinder not to glue may be blocked or leak the influence, if is the glue clogging will manifest from or the plastic dispensing needle and so on place, but the glue leakage degree serious reason similarly will cause the rubber cylinder not to glue, therefore checks the bad seal aspect and promptly solves appears important, the bad seal must check whether because the seal ring consumes the degree is too high, when the rubber cylinder inside the seal ring is long. After the use of time, part of the rubber will wear and tear, resulting in excessive rubber leakage and lead to glue-free rubber cylinder. In order to prevent glue leakage and glue-free rubber cylinder should be inspected in time and avoid high precision chip motherboard glue dispensing can be applied. This is part of the suggestion that the manufacturer of medium-sized Shenzhen glue dispensing machine can provide.

Non-gelling or non-fluidity caused by blockage

Shenzhen dispensing machine manufacturer reminds you that in addition to the problem of poor sealing, it may also be affected by the viscosity of the glue and block the dispensing errors. This is reflected in the blockage of the plastic dispensing needle, which makes the glue unable to drive the dispensing. Generally speaking, the curing speed of the high-viscosity glue is fast, and the driving pressure and coherence of the glue are guaranteed to greatly reduce the blockage caused by the curing. Problem, in order to make the glue flow uniformly and avoid curing and blocking the plastic dispensing needle, this is to ensure that dispensing machine can be used for dispensing of electronic products with high precision and motherboard dispensing.

Black gasket seal

It is worth noting that the plastic dispensing needle belongs to the consumables in the dispensing process. Once there is a blockage, it needs to be discarded to avoid the direct impact on the electronic parts motherboard dispensing and other industries caused by the non-gluing of the rubber drum. The Shenzhen dispensing machine industry is deeply affected by the concept of stability, efficiency, accuracy and other indicators. The concept of the neutral automation is based on this.