東莞市中制自動化設備有限公司

Dongguan CNAUTO Automation Co., LTD.

18929475867

Dongguan CNAUTO Automation Co., LTD.

18929475867

products

作者:點膠機內存卡 日期:2018-11-16 18:17 瀏覽:

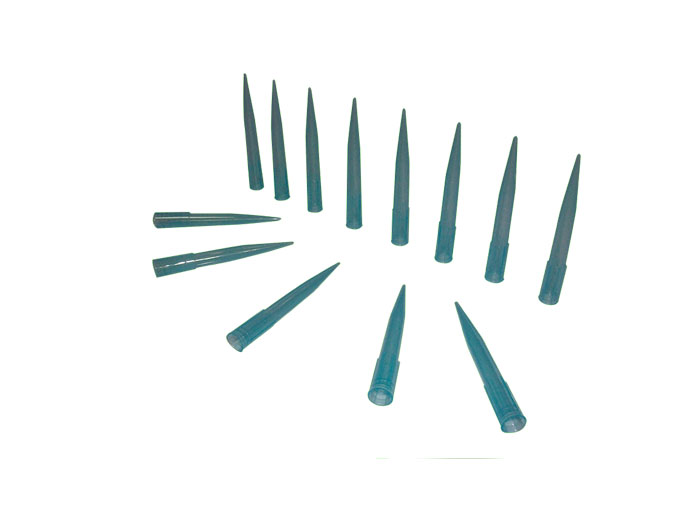

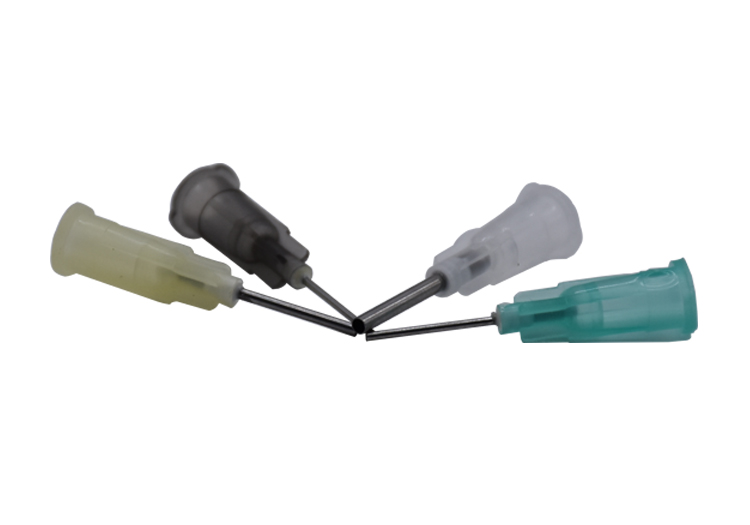

All-aluminium needle is a medium-sized hot-selling product. It can use hot-melt adhesive or red glue. It has high-temperature-resistant quality. It also has very good control over dispensing flow. There are various types and models, such as 14g to 34g, which are basically produced. Specific dispensing needles need to be customized and customized. No less than 1000, because the price is low, so the price of the mold will be expensive.

All-aluminium needle is a medium-sized hot-selling product. It can use hot-melt adhesive or red glue. It has high-temperature-resistant quality. It also has very good control over dispensing flow. There are various types and models, such as 14g to 34g, which are basically produced. Specific dispensing needles need to be customized and customized. No less than 1000, because the price is low, so the price of the mold will be expensive. There are many processes needed in the production of all-aluminium needle. First, we need to make aluminium needle, then combine it with plastic. Then according to the demand of the product, this is the all-aluminium needle. We can rest assured in quality. We have the core technology in the production of needle, using imported technology from abroad. Each needle is carefully manufactured, in order to achieve the industry for all-aluminium needle properties, can meet the quality of more products.

There are many processes needed in the production of all-aluminium needle. First, we need to make aluminium needle, then combine it with plastic. Then according to the demand of the product, this is the all-aluminium needle. We can rest assured in quality. We have the core technology in the production of needle, using imported technology from abroad. Each needle is carefully manufactured, in order to achieve the industry for all-aluminium needle properties, can meet the quality of more products.