Are common dispensing problems associated with rigorous equi

作者:點(diǎn)膠機(jī)廠家 日期:2019-04-18 14:35 瀏覽:

Intelligent CCD visual dispenser can improve the efficiency and quality of production line. In fact, the high degree of intellectualization and rigor of equipment control the common problems of dispensing. Precision controlled CCD visual system solves the problems of dispensing position deviation and quantitative control of dispensing. The demand of sealant coating is controlled and the industry application is more satisfied. Battery cover coating and semiconductor coating The good rate of sealant coating for electronic products such as glue coating can be realized by this equipment. The solution and control of other common problems of bad dispensing are the problems that operators need to pay attention to.

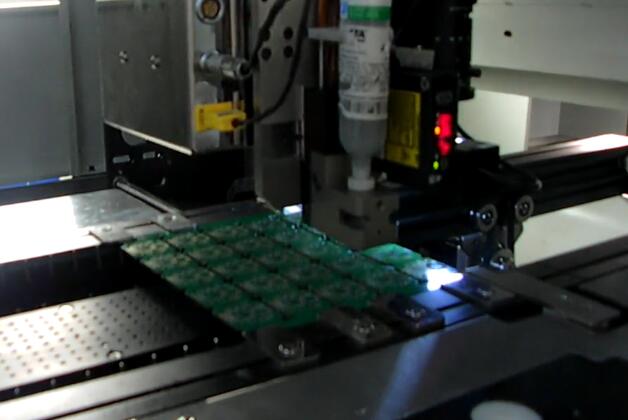

Precision control dispensing

Common dispensing problems in production

The common problems of dispensing are mainly the uneven glue content or the inaccurate control of glue volume. The inaccurate control of dispensing requires fixture fixture to fix the path programming and set the required amount of sealant. When dispensing machine coats sealant, the amount of sealant needs to be strictly controlled. Usually, the air pressure of the connected controller is adjusted to control the amount of glue. This way is not conducive to reducing the occurrence of dispensing problems. Frequency is one of the factors affecting the application quality of battery cover and semiconductor coating industries. Common problems such as glue viscosity, driving pressure, stability and so on are all influencing factors. They have certain influence on the function and rigor of application equipment. It is recommended that intelligent CCD visual dispenser is more effective in frequency control of common dispensing problems.

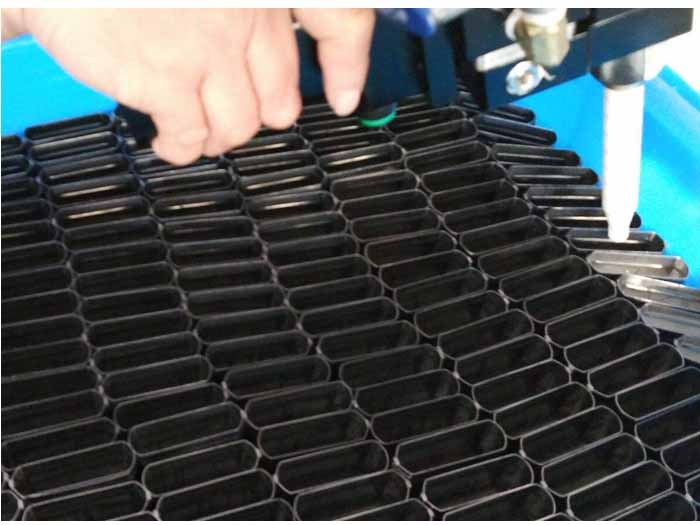

Precision multi-specification dispensing

Why is the stability of CCD visual dispenser strong?

CCD visual dispensing machine locates and inspects by visual function, which is often used in intelligent batch production line. It can meet the efficiency and consistency of batteries and semiconductors for batch production. Visual positioning function is used to scan and inspect the parameters of products, reduce the impact of common dispensing problems, and directly locate the dispensing on the surface of products, thus eliminating the need. In order to meet the requirement of fixture fixture fixture fixture and avoid most manual operation deviation, CCD visual dispensing machine can be used for high precision gluing of battery cover and semiconductor products without special fixture.

Visual dispenser for CCD detection

In recent years, more and more batteries and semiconductor coating batch manufacturing will choose CCD visual dispensing machine for dispensing, because of its advantages of high precision and intelligence, the control quality of common dispensing problems is good and the application efficiency is higher.