How to Make SMT Patch Link Higher Quality, High Speed and St

作者:點膠機廠家 日期:2019-06-17 14:13 瀏覽:

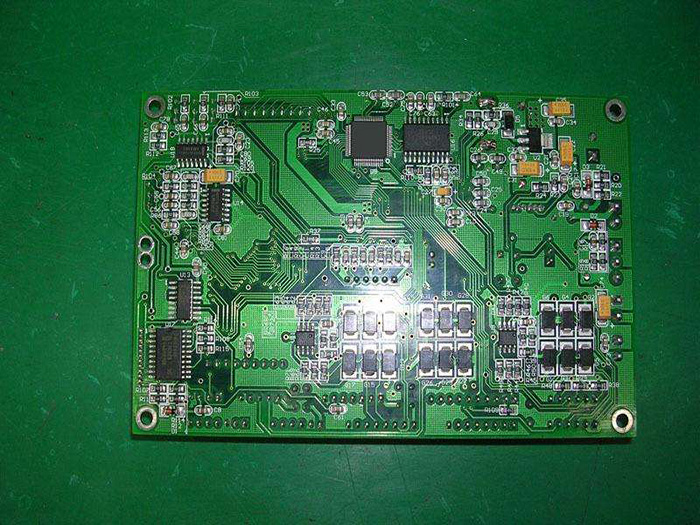

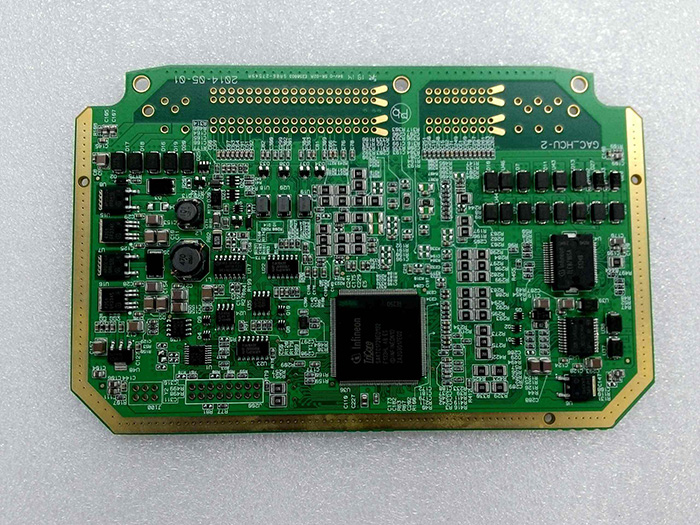

Multiple capacitors, inductances, resistors and other components consisting of the upper end of the circuit board need to be strengthened by a set of related patch strengthening process. The application of SMT patch technology needs the auxiliary application of automatic dispensing equipment to enhance the consistency and synchronization of quality and efficiency. A fully automatic, high-speed and stable red dispensing machine is recommended for SMT small electronic patch technology. The dispenser can precisely control the temperature of red glue and make it suitable for micro-industry applications such as patch coating. After understanding the difference between red glue and solder paste, the dispenser should be adjusted to a suitable bonding state. It is suitable for small SMT patches or PCB board applications which require a high degree of precision.

Smt Patch Processing and Coating

Quality Requirements for SMT Microelectronic Patches

The whole SMT process refers to the positioning and welding fixing of the components of electronic products. The process of the production line of electronic products is more important. It needs to be strengthened and assembled with appropriate amount of red glue on pins or leads. The application industry involved is relatively wide. The SMT patches with high assembly density and small size of components are not easy to control. Red glue or lead are widely used in SMT patches. Solder paste, about the difference between red glue and solder paste need to be adjusted before practical application, SMT process composition includes preparation inspection, inspection process; solder paste printing, inspection process, patch process, inspection and many other patch operation steps, PCB board coating belongs to the application of SMT, at present, small edition more recommend high-speed and full-automatic red glue dispensing machine for a number of patch production. Application.

The application of SMT technology needs to be matched with a dispenser with high speed and precise flow control to achieve complete and effective bonding effect. The 331 position red dispenser is mainly suitable for coating and filling of micro-products. Temperature control device is installed to adjust the temperature of red glue or the bonding temperature of the same type of glue to control the glue. Servo-driven motor ensures long-term stability and high efficiency. High automation degree has stronger advantages in reducing performance and labor cost, especially in PCB board gluing in patch links.

Electronics SMT patch coating

Recommended application of automatic dispensing equipment

Selection of automatic red glue dispenser operation automatic high-speed and stable application effect is prominent, relatively has a strong stability and good execution effect and other direct effects, applied to SMT patch operation of high-frequency characteristics, control appropriate red glue temperature for complete bonding to reduce electromagnetic and radio frequency interference and other effects, can help manufacturers of patch products batch, raw. Production automation, production enterprises to improve their competitiveness to meet customer needs, substantially improve product quality and reduce production costs are intelligent objectives, which are indispensable to the red glue dispenser with strong automation application effect.

Standard red glue dispenser

The volume and weight of electronic products are reduced by 40%~60% and 60%~80% after SMT patch technology application. These visualized data make its application advantages more clear, including the PCB board adhesive bonding and strengthening also need the auxiliary application of this equipment. Red glue and heated solder paste are also suitable for patch assembly, requiring operators to have a preliminary understanding of the difference between red glue and solder paste.