Overheating of high speed dispensing machine for aluminum pr

作者:admin 日期:2017-10-20 16:05 瀏覽:

In the aluminum high speed glue dispensing process, high-speed dispensing opportunity because of the accident situation is not normal operation or product dispensing dispensing glue on the glue dispensing point, area is too large, the position deviation or needle clogging, residual impurities inside problems a lot, this time we mainly discuss the dispensing machine overheating problems.

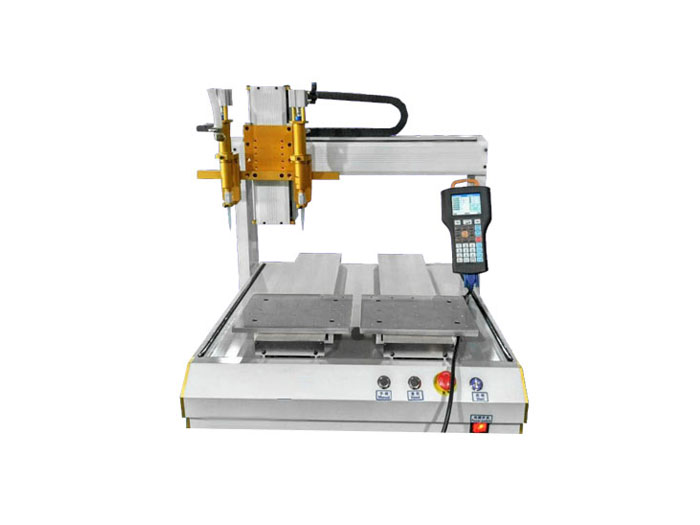

Double head double station aluminum profile high speed dispenser

How to determine whether the dispenser is overheating depends on whether the glue point area of the dispenser is larger than expected. If the original performance is also confirmed the viscosity of glue is very rare, if not with this kind of questions also confirmed that the numerical dispensing machine transmission device set is too large, we detected aluminum high speed dispensing machine after the start of the internal temperature exceeds the expected temperature, if it can confirm the aluminum high profile inside the dispensing machine overheating.

Double station aluminum profile high speed dispenser

After overheating, we need to investigate the cause of overheating. 1. See if the temperature is too high in the working environment. Check whether the heat source is next to the dispenser and affect the temperature in the pipe of the dispenser. 2, whether the heating device is installed in the pipeline, if any, check the heater whether there is any fault, causing the heating value to exceed the temperature value of the original display of the heating device.

If there is any reason above, the solution is as follows:

High speed dispensing machine for multi axis aluminum profiles

1, remove the heat source or work environment to install an air conditioner to adjust the temperature. 2, for aluminum profile high speed dispensing machine heating device maintenance or replacement, or temporarily use the control system to adjust the heating device heating capacity can temporarily solve the problem. 3, using the setting value of the control system to reduce the dispensing time of dispensing needle.