Is there a specific cleaning plan for dispensing machine?

作者:點(diǎn)膠機(jī)廠家 日期:2019-12-02 16:15 瀏覽:

This specific description is the dispensing machine cleaning process and related points for attention

331 platform automatic dispensing machine

I. cleaning of automatic dispensing machine for replacing glue

1. Check what kind of cleaning solution should be used to clean the glue.

2. Close the valve at the bottom of AB material barrel.

3. Use the equipment to release the glue, remove the glue remaining in the glue valve, high-pressure Teflon pipe and ab pump, check the change of the glue amount at the glue valve outlet, and the glue has been exhausted in the analysis.

4. Disconnect the main power supply of the equipment.

5. Remove the rubber pipe at the bottom of the barrel, enable the valve, and discharge the excess glue from the barrel.

6. Close the valve at the bottom of the barrel, pour a small amount of cleaning agent into the barrel, and completely clean the residual glue on the barrel wall and the barrel bottom.

7. Enable the valve at the bottom of the barrel to drain the sewage, and the barrel shall be free of residue.

8. Remove the AB pump, and clean the glue in the pump (this item shall be used by the learning staff who have been disassembled the pump).

9. Install the clean AB pump back to its original position and connect it with the barrel rubber tube again.

10. Replace the high-pressure Teflon tube.

11. Pour in new glue.

12. Start the equipment, jog the glue out for 3-5 minutes, and check that the glue out is normal.

13. Mix again the proportion of AB glue.

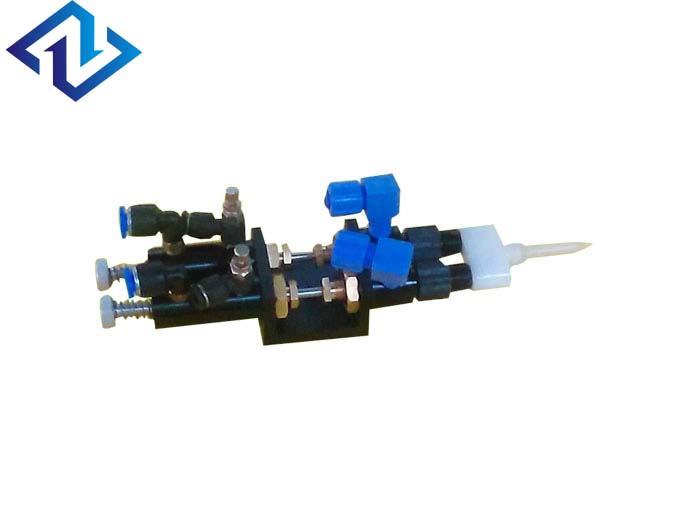

Two component AB control dispensing valve

2. Compared with the first one, the second one is much simpler:

At present, many double liquid dispensing machines are equipped with built-in automatic cleaning function. Only need to add matching cleaning liquid for automatic cleaning. I will not explain it here. This is to explain how the double liquid dispensing machine without automatic cleaning function is cleaned?

1. Look at the characteristics of the glue. If it's a single liquid glue, it's not easy to dry (at normal temperature). Once the same glue is used next time after the product dispensing, the problem of cleaning can be ignored.

2. Once the anaerobic glue is used, the quick drying glue (401, 502) and silica gel glue will dry and solidify quickly at room temperature, so this kind of glue needs to be cleaned. In the case of cleaning, first discharge the unused glue, then put the organic solvent, such as Tianna water and industrial ethanol, into the equipment, then press out the organic solvent together with the glue, and then blow it with an air gun. It is necessary to use this kind of equipment for cleaning, otherwise it will be very difficult for the glue valve to be dried and fixed and the material barrel to be neutralized, and some accessories may need to be replaced, so you must remember to clean after use..

Small AB dispensing valve