What are the factors that affect dispensing accuracy?

作者:點(diǎn)膠機(jī)廠家 日期:2019-12-24 14:45 瀏覽:

Electronic equipment has always been the most critical output standard of automatic dispenser manufacturers. The manufacturers of automatic dispenser and automatic dispenser are willing to compete for the electronic equipment industry. The most important thing to recognize is to do well in production and operation according to the wishes of the middle and lower reaches. At that time, some key factors affecting dispensing accuracy will be described.

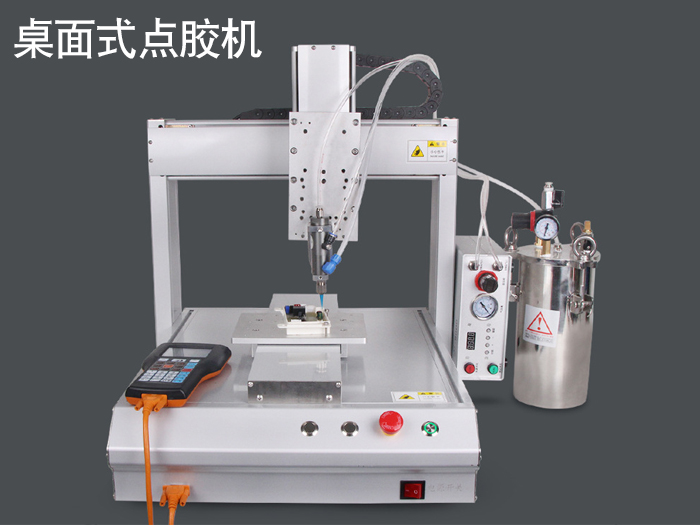

331 automatic dispensing machine

Electronic equipment emphasizes more on customer experience, and lightness is a key development trend. Due to the smaller size of electronic components, the size of components was very common around 1mm. The components on the circuit board are more and more close to each other. In the past, the form of dispensing machine using human eyes to teach and write programs could not be accurately located at the beginning, so it was decided that CCD imaging technology would increase the size of products by 30-50 times, so that on the display, the end of accurate positioning programming could meet the needs of customers' manufacturing.

The CCD with different pixels and the camera with different magnification, and the combination with various light sources, also need to have a very correct control accuracy, in addition to the programming to fit the individual uncertainty of the commodity itself.

The key factors affecting dispensing accuracy are generally the size of part of the glue amount, dispensing pressure, needle size, the distance between the needle and the work, the viscosity of glue, glue temperature, solidification temperature curve, bubbles in glue, and the liquid that is willing to be adjusted uniquely. The next recommendation may also have some help.

Matching automatic dispensing equipment

In the first step, the size of the dispensing amount is generally one-half of the width of the commodity based on the size of the glue point diameter, so it is necessary to ensure that there is enough glue to bond the parts and prevent excessive glue. The amount of dispensing is interfered by the length of time. In practice, the dispensing time should be determined according to the temperature and the characteristics of the glue.

In addition, the level of dispensing accuracy affected by dispensing pressure is generally too large to cause glue overflow and excessive glue volume; too small pressure will cause intermittent dispensing problems and leakage points, so it is attributed to commodity defects, so it is willing to end improvement according to key factors such as working temperature and glue viscosity.

In addition, the size of the inner diameter of the dispensing machine needle is generally 1 / 2 of the diameter of the dispensing point. In the dispensing process, the dispensing needle should be selected according to the commodity size.

As for the separation between the needle and the work, different dispensers choose different needles, some of them have corresponding stopping degree, so that they are willing to master the separation of dispensing. Even before the task starts, the correction of the separation between the needle and the work should be done, i.e. z-axis high degree correction to prevent the influence on dispensing accuracy.

AB glue double liquid dispensing machine

In addition to the key factors of the dispenser itself, the viscosity of the glue also affects the quality of dispensing. If the viscosity is large, the glue point will be reduced, or even drawn; if the viscosity is small, the glue point will be larger, so the product may be infiltrated, and the glue temperature is usually 23 ℃ ~ 25 ℃; if the working temperature has an effect on the viscosity of the glue, the viscosity will be reduced and the viscosity will be increased, and the glue flow will be reduced correspondingly, which is more likely to cause the problem of drawing 。 The manufacturer of the glue setting temperature curve has come to the conclusion that in actual operation, the higher temperature should be selected as much as possible to make the glue have sufficient strength after setting.

In addition, the glue should not have bubbles. A small bubble will make most of the goods without glue; when changing the hose half way, you need to exhaust the gas at the joint to prevent air strike.

There are many key factors that affect the dispensing accuracy, not only a part of the above, but also the effect of multiple forces interaction in some cases. This will establish a higher standard for dispensing process, not only to avoid the occurrence of the situation, but also to find out the cause of the problem according to the actual manufacturing operation steps when the situation has occurred.