Glue sticking on the dispensing needle of aluminum profile h

作者:admin 日期:2017-10-26 15:41 瀏覽:

When we use the aluminum profile high-speed dispensing machine for dispensing, sometimes glue will adhere to the dispensing head, resulting in abnormal dispensing, not only affect the dispensing efficiency, but also affect the progress of the normal dispensing work. So what can we do to reduce this phenomenon in dispensing?.

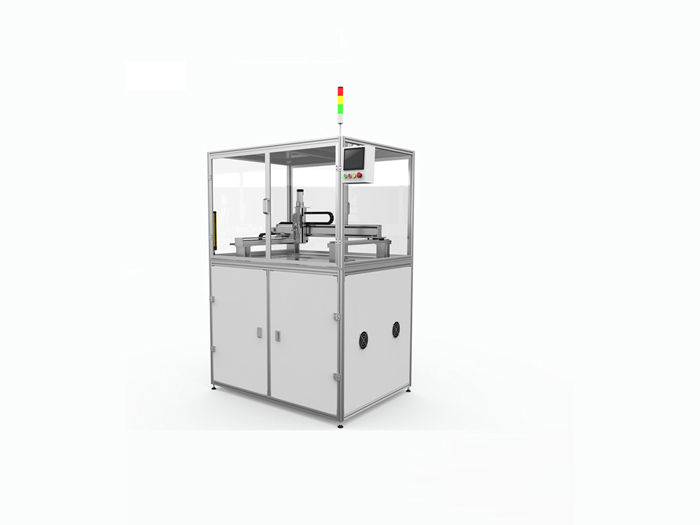

Visual high-speed dispensing machine for aluminum profiles

1, dispensing work environment is too humid

2. Repeated adhesion of instantaneous adhesive

3. Use glue glue that does not accord with aluminum profile high speed dispensing machine

4, in the aluminum profile high-speed dispensing machine processing process is used, glue viscosity is too high, leading to needle clogging phenomenon.

Floor type high speed dispensing machine for aluminum profiles

Main solutions

1, dispensing machine internal pipeline cleaning, dispensing work should not be wet in the use of, and in the dispensing machine installed filter device.

2, check whether dispensing in the work of the use of new instant glue

3. Check whether the glue used in the dispensing work is correct

4, try to let the glue in the dispenser viscosity to maintain a low level.

High speed dispensing machine for large aluminum profiles

Attention: the types of glue are different, the problems and methods are different, so the concrete situation and concrete analysis are needed. Different situations, different treatment.

How to reduce the jam of dispenser

1, improve the temperature of glue, reduce the consistency of glue. For example, hot melt glue machine needle can endure a certain temperature, glue as long as the heat will be removed, eliminate the blockage, so as long as the heater heated to a certain temperature, you can solve the jam machine jam phenomenon. If necessary, a heating device can be added to control the temperature in the pipe.

2, as long as the continuous high speed glue, you can prevent the occurrence of needle clogging. For example, a quick drying dispenser is used to process the product because the quick drying gel at room temperature is rapidly solidified, and if it stops dispensing, it is easy to plug the needle, so the high speed continuity of the dispensing should be maintained.

3, to stop the use of glue, glue can be taken out from the high speed dispensing needle can prevent clogging preserved in dry environment, such as the solidification rate of AB is relatively slow, so it won't happen in a short time solidification phenomenon, but if not a long time production, or production process will happen the blocking phenomenon, so this time you need to mix mouth off, and then glue to prevent blockage of the well preserved, a plastic needle mouth.