What should be paid attention to when the dispensing machine

作者:點膠機廠家 日期:2020-05-03 09:11 瀏覽:

Glue on tempered film Even if the whole process of using glue on the dispenser is strictly carried out according to the operation specifications, there will still be many situations, for example, the glue used drips on the substrate carelessly, or the needle moves slightly, which may not matter to him, because the dispenser is always dispensing, but if you don't care about it, it will interfere with the function of the dispenser In order to effectively reduce the occurrence of this kind of situation, I suggest that the task should be done in the case of glue application. What should be prepared in advance in the case of glue application of tempered film?

Glue on finished tempered film

1. When you use the dispensing machine to glue the toughened film, you need to know clearly the current situation of the dispensing machine. Maybe the dispensing machine is very tired through the daytime task, and the needle can't carry out the dispensing task. At this time, you know that you need to change the needle in the case of gluing, or the needle will move in the case of dispensing, and you must arrange Check the dispensing valve. The dispensing volume of the dispensing machine is very large. The dispensing valve should be changed on time in case of material jamming or other circumstances

2. It is necessary to clean the dispensing machine after the completion of gluing on the tempered film. For example, everyone must wash and wash every day. Because after the dispensing, there may be a lot of surplus glue left in it. The glue has the effect of solidification and must be corroded. Therefore, many parts such as needles, dispensing valves and pressure barrels should be cleaned after the completion of the task Clean thoroughly, if the next day after a night to be used in the case of glue so will interfere with the quality of products.

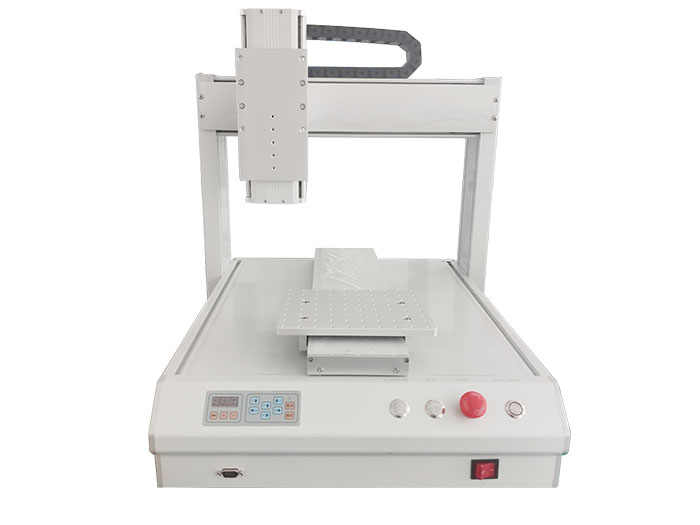

Multi axis filling and gluing machine

3. The user must learn from the reliable dispenser teaching system, and thoroughly understand the application standards and key points of dispensing equipment in order to correctly glue the tempered film.

4. Dispensing machine equipment and dispensing machine operating platform should be stable;

5. The room where the dispenser is placed shall be dry and ventilated to prevent dust from entering and electric shock of the control cabinet;

331 bench dispensing machine

6. Any mechanical structure parts of dispensing machine must be coated with lubricating oil;

7. The total gas of dispensing machine must be above 0.6MPa;

8. The dispenser should be opened once every two days to prevent the raw material from setting when the toughened film is not glued;