What are the problems in the production of the glue dispense

作者:點膠機廠家 日期:2018-02-02 16:50 瀏覽:

The dispenser is increasingly used for electronic industrial production, application scope expanding to the dispensing industry opened a bigger market, but at the same time, there are also a series of problems, such as: glue stability, glue viscosity, curing temperature curve and a series of problems plagued bubble a dispensing machine user. Then the following is a simple explanation of the common problems in the production of the glue dispenser and some solutions.

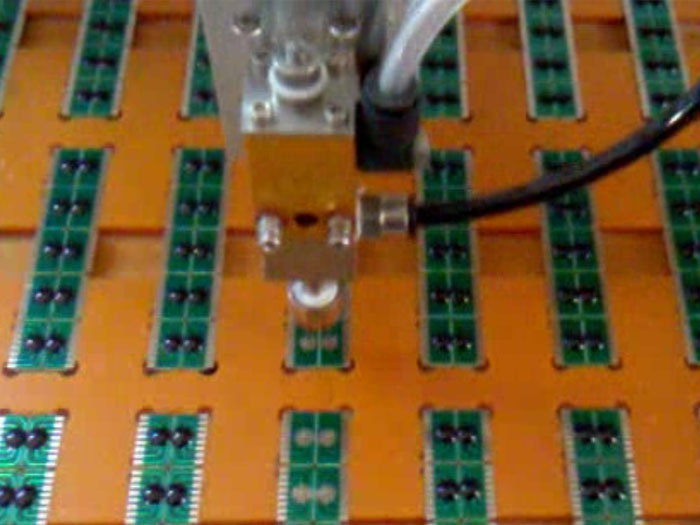

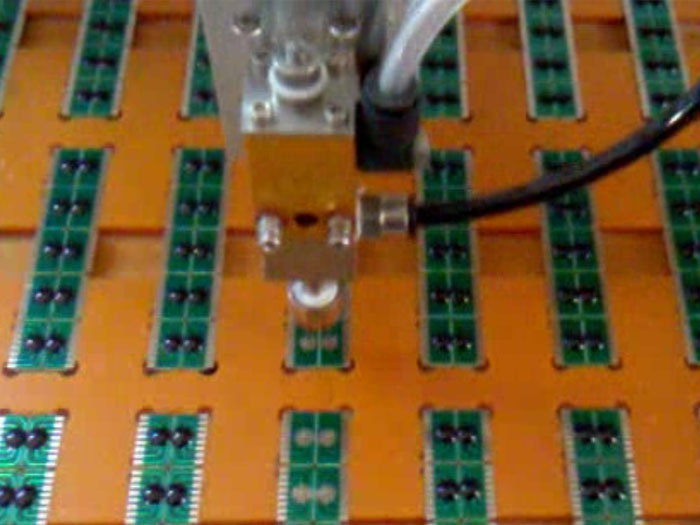

PCB black glue filling

First, the temperature of glue: the general epoxy glue should be kept in the refrigerator at 0--5 C, and it should be taken out 1/2 hours in advance, so that the glue will be consistent with the working temperature. The use temperature of glue should be 23 C --25 C; the ambient temperature has a great influence on the viscosity of the glue, and the temperature is too low, then the glue point will be smaller and the drawing phenomenon appears. The difference of ambient temperature of 5 degrees centigrade will result in the change of the amount of 50% points. Therefore, the temperature of the environment should be controlled. At the same time, the temperature of the environment should also be guaranteed. The humidity and glue dots will change dry and affect the cohesive force. Secondly, the viscosity of glue: the viscosity of glue will directly affect the quality of dispensing. When the viscosity is large, the glue point will become smaller and even wire; the viscosity is small, the glue point will become larger, and then the weld plate may be dyed. In the process of dispensing, the proper back pressure and the speed of the glue should be selected for the glue of different viscosity.

Epoxy resin glue

Again curing temperature curve: for the curing of glue, the general manufacturer has given the temperature curve. In practice, it is necessary to use high temperature to solidify, so that the glue has enough strength after curing. Finally, the bubble problem is often found in dispensing production: glue must not have bubbles. A small small gas will cause many pads without glue; the air in the connection should be emptied when the rubber tube is replaced each time, so as to prevent the occurrence of air beating.

Large scale high speed glue dispenser

These are some of the problems that often occur during the production of the glue dispenser and some simple solutions.