Which industries are applied to electric high speed glue

作者:點(diǎn)膠機(jī)廠家 日期:2018-02-07 17:59 瀏覽:

The electric high speed glue machine is a basic glue dispenser, which consists of the motor head, the back suction button, the controller, the power switch, the digital display and so on. Because electric dispensing machine equipped with suction function, no dispensing conditions, you can manually according to the suction button, avoid glue phenomenon, affecting the effect of dispensing etc.. So the electric high speed glue machine can be used in those industries?

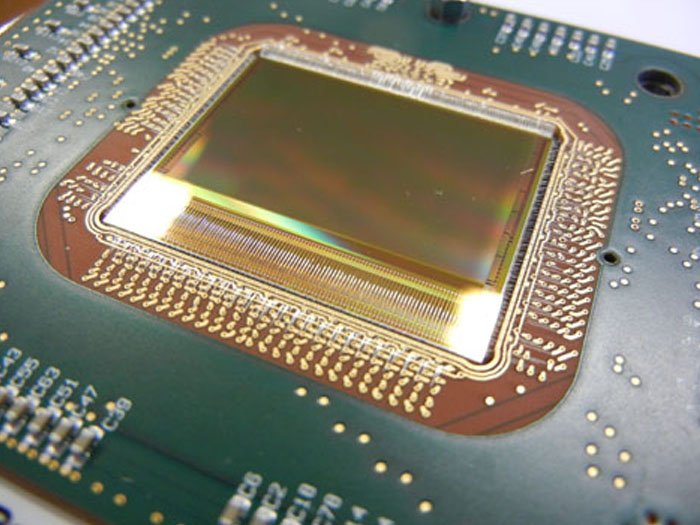

Semiconductor chip packaging

In electronic parts, semiconductor manufacturing, integrated circuits and other products will be used to glue technology. If you use the manual dispensing work, not only needs a lot of manual operation, leakage glue, etc. epoxy can easily occur in the dispensing process, to use some traditional dispensing products requiring high manual dispensing is difficult to complete. In front of that, the electric glue machine is equipped with the back suction function, and there is little leakage in the glue process, and the precision of the glue is high.

Double liquid high speed glue machine

Used in machinery manufacturing industry will be more kinds of glue, such as instant glue, epoxy glue, silicone rubber, the instantaneous dry glue solidification speed faster, solidification phenomenon is easy to appear in the dispensing process, blocking the work effect of dispensing dispensing needle. But the electric high speed glue machine can use the instant glue to carry on the glue work, but when choosing the point glue needle, it is best to choose the inner lining to avoid the solidification of the glue.

Toughened film coating on mobile phone

3. Communication industry

The loudspeaker, interphone, mobile phone key, circuit board and other products in the communication industry can all be used to the electric high speed glue machine. There are a lot of driving modes for the general dispensing machine, such as pneumatic drive, piezoelectric drive, electric drive and so on. Pneumatic drive is controlled by high pressure airflow. The use of piezoelectric driven dispensing machine has the advantages of wide working frequency and fast response. The advantages of using electric drive dispenser are: short response time, high accuracy of dispensing.