How to solve the uneven glue point at high speed glue

作者:點膠機廠家 日期:2018-02-28 15:29 瀏覽:

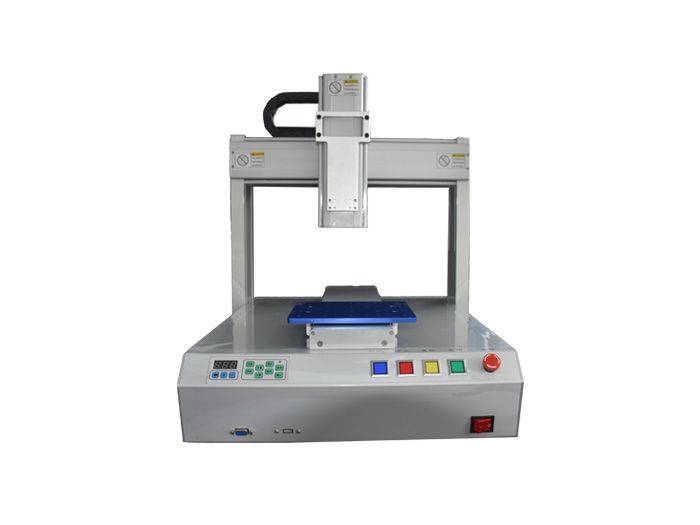

The main application of high speed precision dispensing machine in the production of adhesive execution process, can help the user to complete dispensing work more comprehensive high quality, the user can through high speed precision dispensing machine to improve dispensing quality products, suitable for different production, the most common is the chip bonding on the PCB board. Sometimes the operator in the operation of high speed precision glue dispenser has a problem of uneven glue point, so how to solve the problem of uneven glue point?

Desktop high speed precision glue dispenser

First understand the reasons caused by uneven glue, adhesive strength between only a more comprehensive effect to strengthen product dispensing glue, most of which are through the dispensing pressure driven flow, using high speed precision dispensing machine production mainly to enhance the product quality and yield, the glue may not point out because the pressure caused by insufficient supply, so the operator should make accurate pressure in debugging easy adjustment affect the dispensing accuracy in normal dispensing.

Syringe needle

The dispensing needle may also be potential factors affecting the quality of the gel point, the needle needs long time dispensing work, so in part by high speed dispensing tip friction effect, with glue accuracy is affected by uneven, if needles due to wear and affect the quality of work, the best replacement needles new to avoid glue the accuracy and efficiency of high speed dispensing dispensing machine.

Anaerobic glue

The glue may affect the quality. The poor quality glue is uneven and there are bubbles inside. When used for dispensing, it is easy to cause uneven rubber spots due to bubbles. Therefore, operators should choose high quality glue to enhance the value and dispensing effect of high-speed dispensers.