Application of visual positioning dispenser can provide a de

作者:點膠機廠家 日期:2018-10-12 18:53 瀏覽:

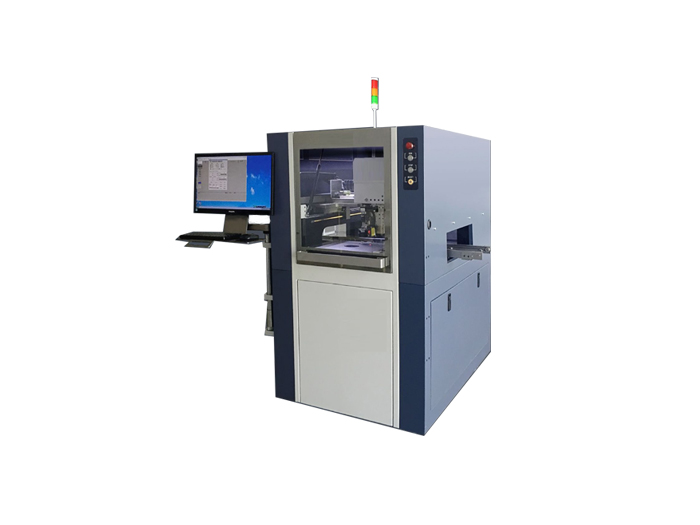

Visual system is the biggest bright spot in the visual positioning dispensing machine. In the process of dispensing production, the operator can know the actual dispensing work condition through the display screen, and the visual dispensing machine in dispensing positioning accuracy effect is very good, in the work before debugging the working parameters, through With the help of visual system, this visual positioning dispensing machine can accurately align dispensing and effectively improve the quality of dispensing products.

Introduction of relevant parameters for visual positioning dispensing machine

Visual positioning dispensing machine type is generally landing, then the dispensing accessories are more complete, for dispensing valves, pressure barrels, dispensing needles and other basic accessories are assembled, this visual dispensing machine with a relatively large platform, in dispensing work can be a number of product parts Complete production work. And the visual positioning dispensing machine is also an intelligent working equipment, in the process of dispensing production, can automatically complete dispensing production, with intelligent positioning dispensing effect can be guaranteed to be 0.01 mm, assembly display screen can also avoid dispensing positioning deviation problem.

Detailed understanding of product dispensing

Visual dispensing system can not only cooperate with the setting of dispensing positioning, but also facilitate the operator to understand the actual work situation when dispensing. When dispensing problems occur, it can also find out the problem through the visual system, which is convenient for the staff to deal with and solve in time. In this visual dispensing machine can be configured with multiple dispensing valves, work without employee operation, in terms of work efficiency can be a great advantage.

In the dispensing work of the product, the visual positioning dispensing machine can be used to understand the dispensing work condition in detail, and the production output of the product can be greatly improved.