How to strengthen the glue quality of high speed dispensing

作者:admin 日期:2017-10-25 14:51 瀏覽:

We should pay attention to what is the type of dispensing glue used in dispensing time, which is how to remove the impurities, residual impurity aluminum high speed dispensing glue, glue glue such identification quality.

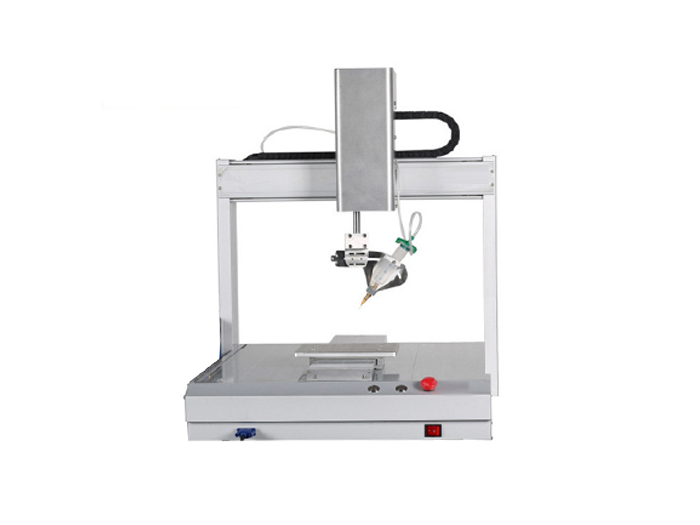

High speed dispensing machine for multi axis aluminum profiles

Aluminum high speed dispensing machine can be used as pressure glue into the dispensing valve at a faster velocity, to achieve the purpose of high speed dispensing, so the use of some sticky glue to glue, because of high viscosity glue glue general velocity ordinary glue is much slower, easily resulting in high speed dispensing caused by broken gum produced drawing the phenomenon of.

Single station aluminum profile high speed dispenser

We should pay attention to the dispensing quality in the dispensing process. We should check the quality of the glue before using the high-speed dispenser, which is related to the actual dispensing effect and dispensing quality. Specific detection methods are as follows:

1. In general, we observe the flow of colloid in high speed dispenser at the horizontal tabletop glass surface. When the glue flows faster, the concentration is low. On the contrary, the flow velocity of glue is slow and the consistency is high. 2, hand try glue viscosity, a little wire drawing phenomenon, a little sticky phenomenon is the best. 3, observe the gel coagulation time on the glass, preferably one or two minutes as the standard. 4, glue solidification after poking with your finger to see if easy to open, that is, glue strength is not enough, if the glue inside the muddy phenomenon is that there is impurities. 4, glue two boards with glue, soak it in water for one day, and observe the glue color to check the water resistance after a day.

High speed dispensing machine for aluminum profiles

If we find that there are additional additives in the test, we can filter out the impurities with filter screen and filter paper.