New paste spray valve recommended for solder paste dispensin

作者:點膠機廠家 日期:2020-06-23 10:07 瀏覽:

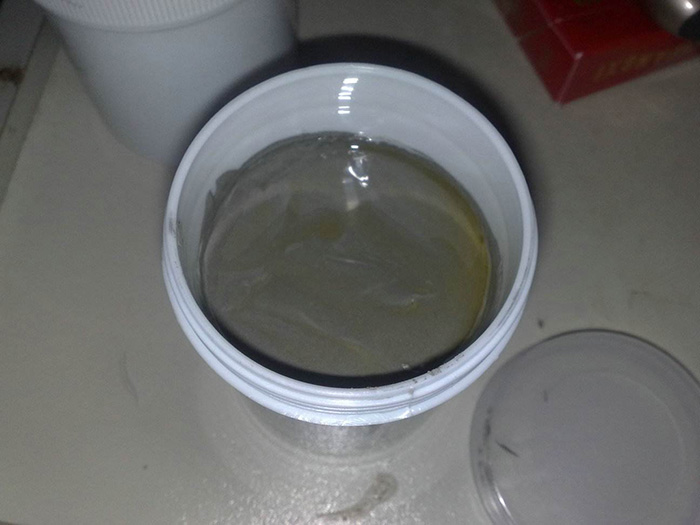

We believe that you have a corresponding understanding of paste, a fluid with high viscosity and poor fluidity. Because of the high market heat and demand of the non-contact glue delivery mode, the paste spray valve is driven by the needs of this part of the industry. This special spray valve can control the glue delivery precisely and stably. The control of paste fluid is more intelligent and full than other types of glue valves There are many kinds of application links that need to be filled with silica gel.

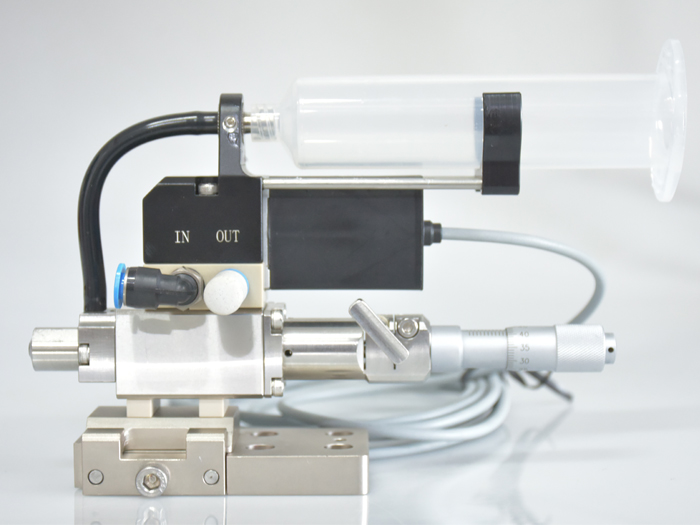

Solder paste spray dispensing valve

At present, the common solder pastes on the market are basically medium high viscosity colloids, with poor liquidity and difficult to control. The conventional dispensing valve can not be used for complete and precise control at all. The solder paste spray valve is electrically driven to spray out the solder paste, and the glue is delivered at a high frequency of 280hz, with a single point delivery accuracy of 2nl. With this high-precision centralized spray effect, it meets most needs To produce high-precision spray solder paste industry, it has strong flexibility and fast execution speed. It is also supported when it is added to the platform machine.

Spray type automatic dispensing valve

The solder paste spray valve is applicable to a variety of viscosity fluid control glue, so it can be applied to most of the current fluid control spraying. The stability of piezoelectric spraying will be more advanced and prominent compared with the previous methods. The solder paste spray valve supports a variety of irregular paths and arc spraying glue, ensuring that the solder paste can be sprayed to the coverage position required by the product. As a whole, it is comprehensive and can be used for Labor saving and cost saving also have the advantages of implementation.

The spray diameter of the non-contact solder paste spray valve can be controlled at about 0.4-0.5. It can complete the precision spray stability control with modular design, actuators, fluid standard chambers, tappets, nozzles of various specifications, etc. Therefore, it can develop replacement plans according to the actual needs, which can meet the different manufacturing production.