Power motor of micro five axis high speed dispenser

作者:點膠機廠家 日期:2017-11-20 16:42 瀏覽:

The dispensing process is relatively complex single execution micro dispensing every link may affect the final effect, need to do the preparatory work, the five axis high speed dispensing machine is a machine capable of performing repetitive micro dispensing equipment, including dispensing work power by the power motor provides special configuration.

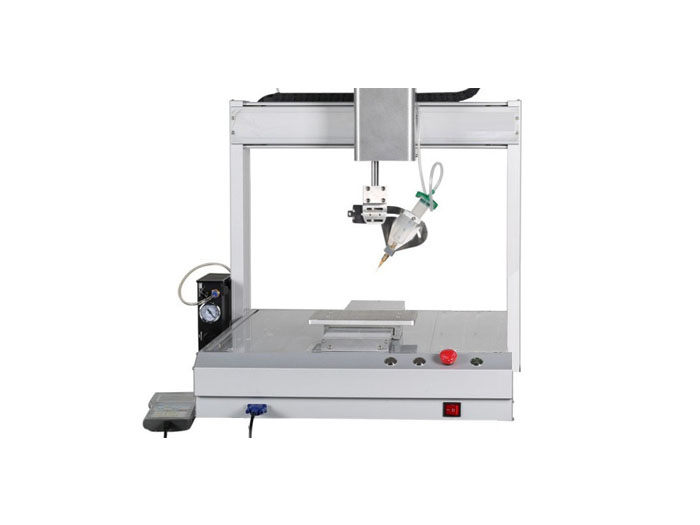

Single station five axis high speed dispenser

The driving motor is also called motor, by converting electrical energy into mechanical energy to work for the implementation of dispensing highly repetitive dispensing machines, which force moving the power wire and assured the direction of the magnetic field between the number of dispensing motor is the magnetic field on the current stress of work.

Power motor for dispensing machine

The working principle of the five axis high speed dispensing machine dedicated power motor is more complex, the electric pulse power motor into a major driver, when the power motor receives the micro dispensing signal will work according to the contents of the implementation of five axis signal trace point glue accordingly, also called the step angle. Through the stepping angle five axis high speed dispenser, the micro dispensing work can be carried out accurately, and the working speed of the power motor can be independently controlled according to the demand.

Five axis high speed dispensing machine

In fact, the power motor acts as an actuator when the five point dispensing is performed on the high speed dispenser, and when the main actuator transfers the signal to the power motor, it will be transmitted by step angle. The rotor and the computer encoding parts are used in the internal power motor composed of alloy permanent magnet material, power motor moment in high-speed operation and not easy to damage, and the power to provide a stable, so it can help the five axis dispensing machine is stably performed high speed micro dispensing work for a long time. The maintenance of power motor needs cleaning the stator rotor, replacing the worn parts, dipping paint, drying and adjusting the dynamic balance.