From the use of visual dispensing machine, what are the char

作者:點膠機廠家 日期:2020-01-08 09:52 瀏覽:

In many areas, the dispensing process is also called gluing or even dropping. That is to apply electronic glue, oil or even other liquids to the products, so that the products can have the effects of sticking, potting, insulation, stability, surface smoothness, etc., which is mainly used by the automatic dispensing machine or visual dispensing machine. It is often said that only glue and dispensing are needed The area of needle and high-precision dispensing needle needs dispensing.

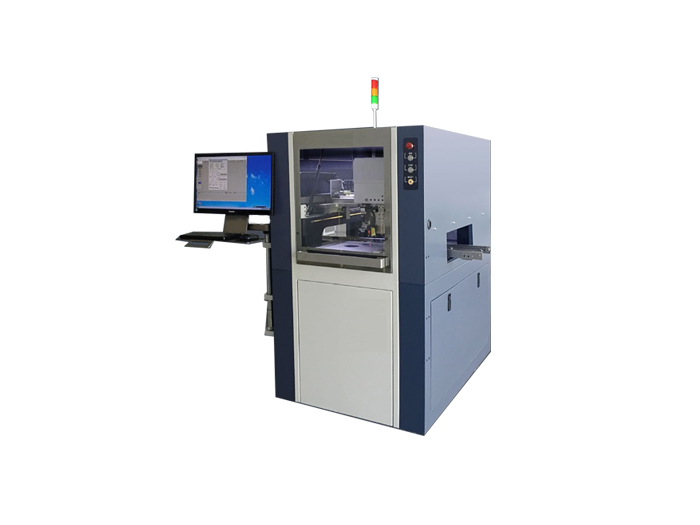

Large visual control dispenser

Electronic products are the fastest progress in modern times, and the application field of dispensing technology is very common nowadays, and electronic packaging technology is also the key information of system packaging technology, so in this small edition, we think it is very necessary to know some other matters that we must pay attention to when applying dispensing technology to electronic products.

On the one hand, it should be noted that the glue used in SMT is widely used in the wave soldering steps of surface assembled electronic devices, such as chip components, sot, SOIC, etc. the glue dispensing process to stabilize the surface assembled electronic devices on PCB with glue is to prevent the electronic devices from loosening or dislocation under the effect of high temperature wave peak interference. Usually, the visual glue dispenser is selected for hot solidification of epoxy resin during production Class a glue, instead of using acrylic acid glue (it needs to be solidified by UV light).

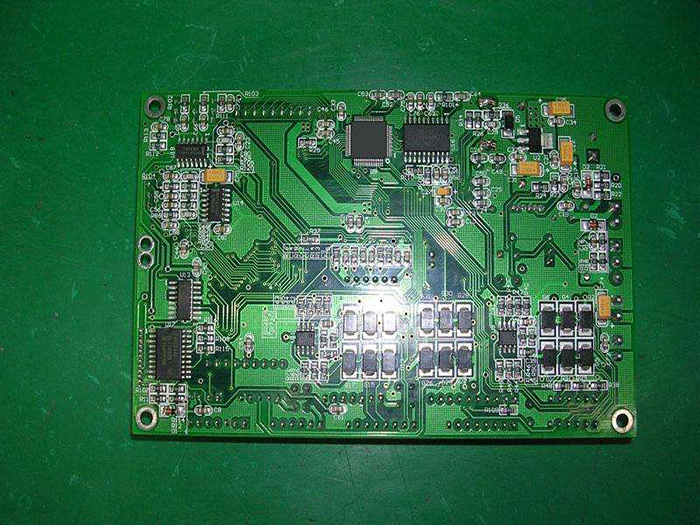

SMT patch processing and gluing

The same other provisions for glue: glue shall have good thixotropic characteristics, no drawing, high wet strength, no bubble, low setting temperature of glue, fast setting, sufficient setting strength, low moisture absorption, excellent maintenance features, no toxicity, easy to distinguish color, which is conducive to check the quality and packaging of glue points. The packaging form should be simple in the use of visual dispensing machine, and the process adjustment plays a key role in the dispensing process.

On the other hand, the adjustment of dispensing quantity, dispensing pressure (back pressure), needle height, distance between dispensing needle and PCB board, glue temperature, glue viscosity, solidification temperature line, bubble and other specifications will directly or indirectly interfere with dispensing quality.

460 UV glue

Dispensing is a whole step, no matter in which any specification change will interfere with other fields, so we must pay attention to the synergy in the dispensing process.