How to remove the gel of high speed dispenser?

作者:點(diǎn)膠機(jī)廠家 日期:2020-01-13 09:39 瀏覽:

Heat to remove the gelled glue on the dispensing needle, because the gelled glue and led conductive silver glue have a very fast solidification efficiency. Once the dispensing needle of the high-speed dispensing machine with gelled glue is not well selected, it is more likely to cause the glue to solidify in the needle. Finally, the impact of the glue is blocked and the dispensing is accurate. Therefore, it is necessary to remove the gelled glue. This is due to the installation procedures in some dispensing machines When the gel solidifies on the dispensing needle, it can run the heating program to make the glue inside the needle melt open. After the opening, the dispensing needle can be cleaned. After the excess glue is scrubbed and cleaned, it can be manufactured again. The dispensing work can be carried out to prevent the impact of the gel blocking on the dispensing work. It is also a very good method to remove the gel.

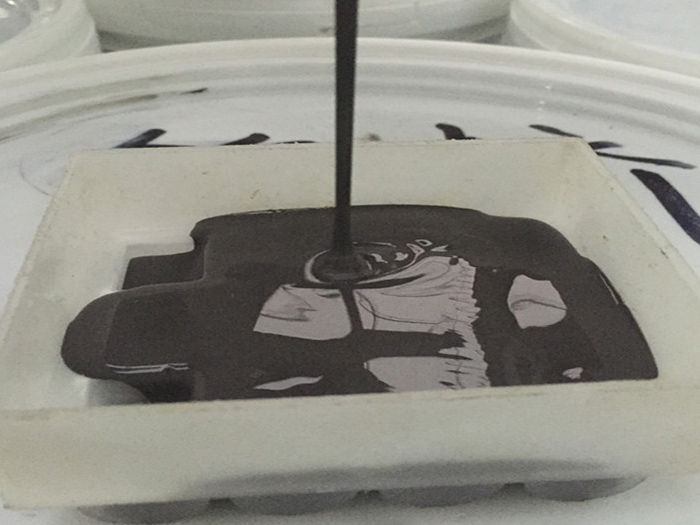

Filling and coating of gelling compound

It is not allowed to use glue with impurities. Not only is the characteristics of gelled glue, but the glue is blocked by the needle of high-speed dispenser. Once the quality of the glue used is not good, the impurities in the gelled glue during the use process are more likely to block the dispensing needle, and finally the gelled water in the needle will gradually solidify. In the dispensing process, once you see that the quality of glue is poor, immediately end the dispensing work, wipe the high-speed dispenser to replace the glue, so as to prevent the impurities of the gel from blocking up and affecting the glue output. In this way, the gel is not conducive to removing impurities, so only high-quality gel can be used to carry out dispensing to reduce the frequency of removing the gel.

Table top high speed automatic dispensing machine

In fact, there are many ways to remove the gel:

1. When there is glue dripping from water scrubbing, it needs to be scrubbed immediately,

2. Chemical scrubbing only has an impact on the environment

3. Repeated liquid scrubbing is also the most appropriate form for production, that is, it can be reasonably used to remove the gel, reduce the cost of the company, and it is also a reasonable form of use.